| |

|

|

|

|

|

|

|

|

|

| |

| Processing methods |

| |

|

| |

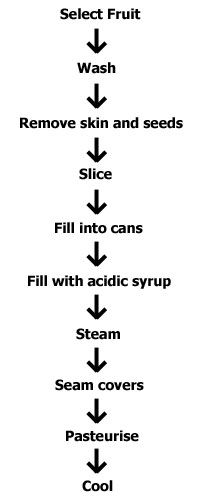

Use mature and firm fruit for canning. Clean selected fruit with water, peel, and cut into halves. Remove the seed core and slice guava into smaller slices. Fill cans with the slices and pour hot syrup at pH 3.7 into the cans. Steam the cans in an exhaust for 2 minutes. Seal the cans and pasteurise for 7 minutes in boiling water. Cool the cans in running water until the temperature is reduced to 45ºC.

Guava slices processing |

| |

|

| |

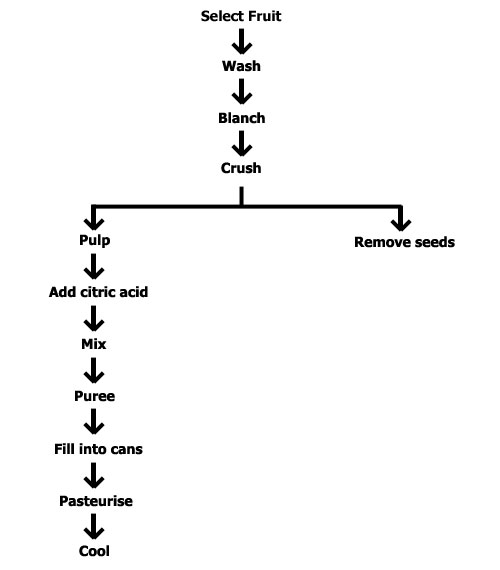

Use ripe, soft fruit for purees. Firm fruit must be ripened with ethylene gas before they are soft enough for processing.

Wash fruit, remove all black spots and chop fruit into small pieces. Blanch in hot water for 3-5 minutes. The fruits need to be blanched to prevent the puree from turning brown during processing. Crush with a pulper. Remove seeds and extract pulp for puree. Adjust the pH with citric acid to a pH of 3.7.

The puree is pasteurised with the Ultra Heat Treatment (UHT) at 121ºC for 2-3 minutes. Then they are filled into cans, sealed and cooled in running water until the temperature is reduced to 45ºC.

The puree may also be pasteurised at 90-95ºC for 10 minutes. With this method, the puree is filled into cans, sealed and steamed before pasteurisation. The tins are then cooled to 45ºC with running water.

Guava puree processing |

| |

|

| |

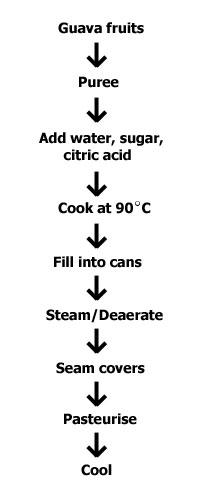

Use guava puree or ripe guava fruits for beverages. Ripe fruits should be pureed before being processed into beverages.

Add at least 5% of guava puree with water, sugar and citric acid and adjust for sweetness. For nectar, the product should contain not less than 35% puree.

Beverages may also contain carbon dioxide, preservatives, colouring, flavouring and permitted food conditioners.

Guava beverage processing |

| |

|

| |

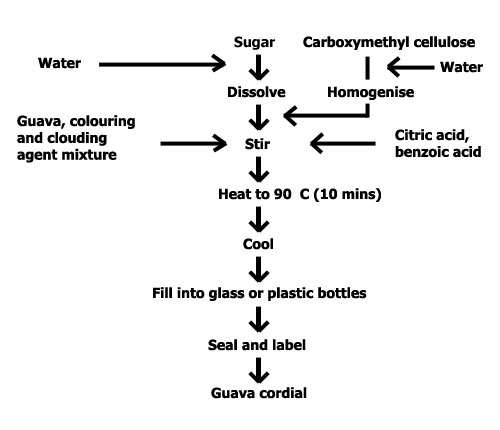

Guava cordial consists of water, guava puree, syrup and stabilisers. Cordials must contain at least 25% guava puree.

Guava cordial processing |

| |

|

| |

Guava nectar is made with guava puree, water, sugar and citric acid and canned without preservatives. Nectar is diluted with water at a 4:1 ratio before consumption.

DRAFT CODEX STANDARD FOR GUAVA NECTAR DRAFT CODEX STANDARD FOR GUAVA NECTAR

|

| |

|

| |

| Guava jam consists of 35% guava puree with 55% sugar, 0.5% pectin and 0.4% citric acid. All the ingredients are mixed and cooked until the mixture attains 65-68º Brix. Guava jam is bottled while hot. Guava jam in air-tight containers may keep for more than a year without preservatives. |

| |

|

| |

Guava jelly is made with pectin, sodium nitrate, sugar, guava puree and glucose syrup that is cooked until the total soluble solids reach 78º Brix. Citric acid is added to reduce the pH. The mixture is cooked to 108ºC and stirred thoroughly. Cool the mixture to 98-100ºC and pour into floured moulds. Let cool for 12-24 hours. The jelly is removed from the mould, dusted of flour, moistened with steam and tossed in icing sugar. |

| |

|

| |

Mix guava puree with sugar, pectin, edible gum and citric acid. Boil the mixture and dry in desiccating trays at 60-70ºC for 4-5 hours. The product consisting of 2 mm thick sheets that can be rolled into fruit rolls. |

| |

|

| |

Soak guava in 10% brine for 1-2 weeks. Cut guava into bite sizes and soak in a solution containing a crisping agent for 4 hours. Rinse the fruit and fill into bottles. Pour syrup containing 35-40% sugar, citric acid and preservatives into bottle and seal. Store pickle for 7 days before consumption. |

| |

|

| |

|

| |

| |

| |

| |

|

|

|

|

|

| Names |

| |

|

|

|

Psidium guajava |

|

|

Common: |

|

English: |

guava |

Indonesia: |

jambu batu |

Malaysia: |

jambu batu |

Tagalog (Philippines): |

bayabas, guyabas |

Thai: |

farang, ma-kuai, ma-man |

| Tamil: |

koiyappalam |

Mandarin: |

fanshiliu |

Lao: |

si da |

Vietnam: |

oi |

Cambodian: |

trapaek sruk |

Burmese: |

malakapen |

|

|

Taxonomic Position: |

| |

|

Domain: |

Eukaryota |

Kingdom: |

Viridiplantae |

Phylum: |

Spermatophyta |

| Subphylum: |

Angiospermae |

Class: |

Dicotyledonae |

Order: |

Myrtales |

Family: |

Myrtaceae |

| |

|

| Other Names Used: |

| |

| Psidium aromaticum |

| Psidium cujavillus Burm. f. |

Psidium pumilum Vahl

|

|

|

|

|

|

| |

| |

|