| |

|

|

|

|

|

|

|

|

|

| |

|

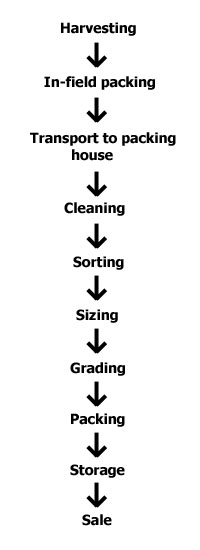

Schematic diagram of post-harvest handling |

|

Postharvest handling of papaya requires care and attention to detail. Papaya is susceptible to several factors that can reduce its marketability, including extreme or fluctuating temperature, moisture, disease, and mechanical damage. Exposure to these factors through inappropriate handling can cause under- or over-ripening, inconsistent quality, and poor flavour and result in high postharvest losses. If properly cared for, papayas can sustain a shelf life of 4 to 6 days under ambient tropical conditions (25°C to 28°C), or up to 3 weeks under lower temperatures (10°C to 12°C).

|

| |

|

| |

Only pyriform-shaped hermaphrodite fruits are selected and graded according to the stage of ripeness (maturity index) and size for export. The fruits are classified as large (601-800 g), medium (351-600 g) and small (250-350 g). Large and medium fruits are normally exported to Singapore, China and the Middle East while the small fruits are marketed in Europe. At present, Eksotika papaya is not exported to Japan, Australia, New Zealand and the United States of America because these countries have very strict quarantine regulations which require postharvest disinfestation. |

| |

|

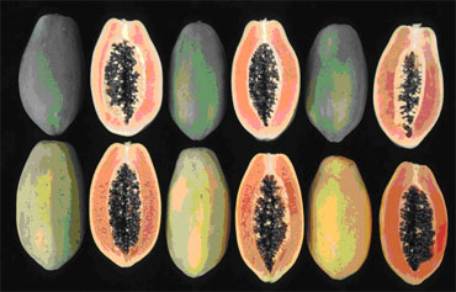

The ripening of the Eksotika papaya is divided into 6 stages of skin colour as follows:

Colour index 1 : full green

Colour index 2 : green with trace of yellow

Colour index 3 : more green than yellow

Colour index 4 : more yellow than green

Colour index 5 : yellow with trace of green

Colour index 6 : fully yellow

PLATE 1: Maturity indices of papaya:

Top row, L to R: Index 1-3

Bottom row, L to R: Index 4-6 |

| |

|

At the packing house the fruits are sorted according to size, shape (sex), colour index, deformation (carpellody) and damages due to pest, disease, mechanical injury etc. For Eksotika, fruits weighing less than 250 g or over 800 g are considered out of the accepted range. Damaged, deformed, overripe and round (female) fruits are also rejected. Sorting is important especially if the fruits are meant for export. Only fruits with colour index 2 are accepted for export. Fruits with colour indices 3 to 5 are usually sold in local markets. Fruits with colour index 6 are overripe and rejected. After sorting, the fruit stalks are cut to a length not more than 5 mm. The fruits are then washed in running tap water to remove latex, dirt, insects and foreign matter. |

| |

|

Damage to the skin immediately after harvest, as a result of careless handling, over-filling of crates and excess movement of fruit during in-field transport, will result in latex staining, punctures, scars and bruises. During ripening, bruised areas will develop into dark soft regions that become infected by fungi and bacteria. Similar effects can occur as a result of poor handling during washing, grading and packing. Taking protective measures throughout the handling procedures can reduce damage. Staff should be trained with harvesting techniques, foam should be included in the base of field crates and crates should contain only one layer of fruit. Stems should to be removed in the field to prevent puncturing or scratching of adjacent fruit. Vehicles used to transport the fruit from the field to packinghouse should be driven slowly and with care. During handling in the packinghouse, fruits should never be thrown or dropped and in automated operations, all machinery should be padded where possible.

Skin abrasions result in blotchy colouration such as green islands (areas of skin that remain green and sunken when the fruit is fully-ripe) and accelerate water loss. Abrasion and puncture injuries are more important than impact injury for papayas. |

| |

|

|

Anthracnose Colletotrichum spp . disease is prevalent during long term storage and with humid orchard conditions, inappropriate pre-harvest disease control or poor orchard hygiene. The presence of the disease is characterised by small black or light brown spots that gradually enlarge and may coalesce and sink.

Phomopsis rot caused by Phomopsis caricae-papayae begins in the stem end or a fruit skin wound and can develop rapidly in ripe fruits; invaded tissue softens and darkens slightly.

Alternaria rot caused by Alternaria alternata follows chilling injury of papayas kept at temperatures below -12°C. |

| |

|

Storage of unripe papaya below temperatures of 10°C will result in chilling injury. The symptoms include surface pitting, discolouration of the peel and the flesh, incomplete ripening, poor flavour and increased susceptibility to disease incidence. Ripe papayas will store successfully at lower temperatures, but transport of ripe fruit (more than 50% yellow colour) is not recommended due to the susceptibility to mechanical damage and bruising. |

| |

>> |

|

High Temperature problems

|

|

Exposure of papayas to temperatures above 30°C for longer than 10 days results in heat injury (uneven ripening, blotchy ripening, poor colour, abnormal softening, surface pitting, accelerated decay). Quick cooling to 13°C after heat treatments minimizes heat injury. |

| |

|

Some exporters use this method of treatment to reduce postharvest diseases especially if the fruits are exported by sea. It is not necessary for fruits transported by air or marketed locally. After washing, the fruits are dipped in hot water at 49ºC for 10 minutes. The fruits are then cooled under running tap water for 10 minutes before fungicide treatment. |

| |

|

Fruits for immediate fresh consumption do not need to be treated with fungicides. However, fruits, which are to be stored or exported, are treated with propiconazole suspension containing 250 ppm active ingredient for 5 minutes. Dipping the fruits in fungicide helps to control postharvest diseases such as anthracnose (Colletotrichum) and stem end rots (Botryodiplodia, Phomopsis). After the dip, the fruits are air dried on racks that have been cushioned with polyurethane foam or sponge. Fans can be used to speed up the drying. |

| |

|

The fruits are packed in a single layer in telescopic corrugated fibre board (CFB) cartons with the stem end facing the bottom of the box. Before arranging them in the CFB cartons, each fruit is inserted in a polyurethane sleeve or wrapped in newspaper. These wrapping materials will protect the fruit from bruising during transportation. The fruits are packed in 6 kg boxes containing usually 6-18 fruits per box. This type of packaging is normally used for export by air or for short distance transportation by sea to Hong Kong. For the larger Sekaki variety, the packaging is in 20 kg boxes, with each box containing from 12-18 fruits.

PLATE 1: Standard 6 kg packaging for export of Eksotika papaya

For long distance sea shipment, the fruits are packed in modified atmosphere packaging (MAP). To create the modified atmosphere (MA) environment the CFB cartons are lined with 0.04 mm thickness low density polyethylene (LDPE) bags in which the openings are tied with rubber bands. In each bag, 40 g of ethylene absorbent (brand name ‘Cleanpack') is wrapped together with the fruits to retard the ripening process during the journey. With this type of packaging, the fruits can be exported by sea to the Middle East. The MAP at storage temperature of 10 - 12 ºC will maintain the quality of Eksotika papaya for 3 weeks. This period is sufficient to cover the journey (10 - 12 days), the customs and quarantine checks at the ports (1 - 2 days) and distribution and marketing of the fruits (6 - 7 days). |

| |

|

| Fruits with colour indices 2 and 3 can be stored at ambient conditions (25 – 30ºC) for 5 to 7 days while fruits at colour indices 4 and 5 can only last for 2 to 3 days. Fruits meant for air freight around the world should be stored at 10 – 12ºC, which would allow for storage periods of 2 weeks or more. With MAP, the storage period can be extended to 3 weeks which is sufficient for sea shipment to Hong Kong and the Middle East. |

| |

|

Domestic market

The domestic market seldom requires value-added or cosmetically enhanced packaging. Therefore, fruits at colour indices 2 and 3 are packed simply in stackable plastic, reusable baskets or containers and transported using trucks without refrigeration.

Export market

Refrigerated reefer containers operated at 10–12ºC are suitable for sea-transport of papaya in CFB cartons (with and without MAP). The 40-foot containers can hold a mixed load of about 2000 to 3500 boxes of Eksotika (6 kg box) and Sekaki (20 kg box). In export by air, each pallet can hold 204 boxes of Eksotika (6 kg box).

PLATE 2: 40-foot refrigerated reefers for sea transport of Eksotika papaya to Hong Kong

Papaya ripens at 15 - 30ºC and temperatures below 15ºC (as in the reefer) and low ambient temperature during winter will retard ripening. To overcome this problem, fruits are removed from the MAP packaging on arrival and ripened at 25ºC in the flow-through ripening room with relative humidity of 85-90%. The fruits are induced to ripen with a 24-hour exposure to 5 ppm ethylene gas. Another method is to induce papaya fruits to ripen with a short exposure to ethylene before packing into the refrigerated reefer containers. |

| |

|

| |

|

| |

| |

| |

|

|

|

|

| Names |

| |

|

|

|

Carica papaya |

|

|

Common: |

|

English: |

papaya, pawpaw |

Indonesia: |

papaya, gedang, kates |

Malaysia: |

betek, ketala |

Tagalog (Philippines): |

kapaya, lapaya, papaya |

Thai: |

loko, makuai, malakor, thet |

| Tamil: |

pappali |

Mandarin: |

mugua |

Lao: |

houng |

Vietnam: |

du du |

Cambodian: |

doeum lahong, ihong |

Burmese: |

thimbaw |

|

|

Taxonomic Position: |

| |

|

Domain: |

Eukaryota |

Kingdom: |

Viridiplantae |

Phylum: |

Spermatophyta |

| Subphylum: |

Angiospermae |

Class: |

Dicotyledonae |

Order: |

Violales |

Family: |

Caricaceae |

| |

|

| Other Names Used: |

| |

| Carica peltata Hook. & Arn. |

| Carica posoposa L. |

Papaya carica Gaertn.

|

|

|

|

|

|

| |

| |

|