| |

|

|

|

|

|

|

|

|

|

| |

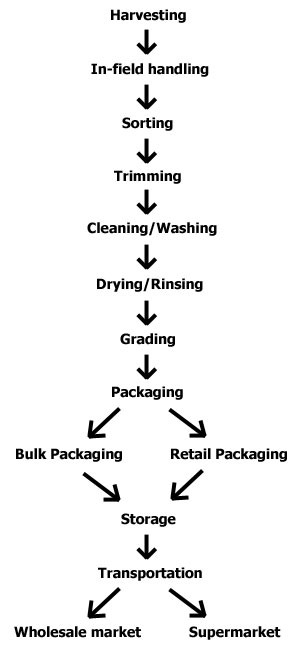

Schematic diagram of post-harvest handling

Figure 1: Postharvest handling of rambutan |

| |

|

Transportation to packinghouse

|

|

| |

Small or medium sized lorries may be used to transport the rambutan to the packinghouse. If the farm is near to the packinghouse then a small trailer will be sufficient. Irrespective of the type of vehicle, careful handling during loading is highly essential. The loading of containers into vehicles should carefully consider the stacking height, arrangement and ventilation.

Ventilation provides air exchange to cool the fruit. If the fruit are not ventilated, heat builds up due to respiration and the storage life decreases. Water is sprayed onto the fruit to reduce water loss which causes shrivelling of the hair and reduces the quality of the fruit. The hair of the fruit will turn dark rapidly and this indicates that the fruit are not fresh.

Conventional lorries should be covered with tarpaulin sheath during transportation especially under unfavourable weather conditions. Farm roads should be kept in good condition because great damage can be inflicted on produce carried over rough roads in unsuitable vehicles. Extreme care should be taken during unloading of the produce at the packinghouse.

Once at the packinghouse the rambutan are sorted, washed, packed, labelled and stored as described below. |

| |

|

| |

| Packinghouse can be a simple shed which is similar to the in field collection centre or a complex equipped with all the necessary facilities. A series of essential preparatory steps are carried out to rambutan prior to subsequent marketing or temporary storage. The operation includes sorting, washing, grading and packing. |

| |

|

| |

| Freshly harvested rambutan are sorted for uniformity in size, shape and colour. Heavily bruised, discoloured, broken and decayed fruits should be removed. Disease-infected fruits should also be rejected to avoid cross contamination. |

| |

|

| |

| Washing is conducted to remove the dirt, fungicide residue and at the same time provide a precooling effect to the fruits. In order to reduce the incidence of decay, chlorine is needed to add to the wash water (100ppm). The washing water should be changed regularly to avoid contamination. |

| |

|

| |

Drying removes excess surface water from the rambutan. The rambutan can be placed on the rack for the drying. Avoid exposure to direct blower during the drying process. |

| |

|

| |

Quality criteria include: fruit size, shape, and weight; bright skin and spine colour; uniformity; absence of defects; and freedom from disease and insects.

Horticultural Maturity Indices: Skin and spine colouration is the main determinant of maturity. Fruit having green skin and greenish-red spines are sour. Fruit should have both skin and spines red or yellow, depending upon variety . Between these two stages, sugar content increases about 20%, and acid levels are half that at the green stage. The acceptable stage is 16 to 28 days after colour break, at which time the skin and spines are brightly coloured. Over-ripe fruit have a watery texture, which may be a senescence -induced tissue breakdown.

Grades, Sizes and Packaging: see the draft Codex Alimentarius standard for details of rambutan size codes for fruit.

Size specification of rambutan presented as single fruit

Size code |

Weight per Fruit (grams) |

Number of Fruits per Kg |

1 |

>50 |

<20 |

2 |

40-50 |

20-25 |

3 |

32-39 |

26-31 |

4 |

26-31 |

32-38 |

5 |

<26 |

>38 |

Size specification of rambutan presented in bunches

Size code |

Number of Fruits per K |

1 |

=28 |

2 |

29-34 |

3 |

=35 |

Fruit are usually sold in 2.25 kg and 4.5 kg, one-piece, fibreboard cartons. Sometimes fruit are pre-packed in punnets. |

| |

|

| |

Packaging provides convenient units for marketing and distribution of products. Packages must protect the contents against undue damage during distribution and must maintain their shape and strength.

Retail packing

Rambutan for retail can be in whole or in minimally processed form. The use of polypropylene containers is suitable to pack rambutan in the minimally processed form. Polyethylene bags are used to pack whole fresh fruit for the retail market.

Bulk packing

Returnable high density plastic containers are suitable for the packing of rambutan in bulk for transportation from the farm to the packinghouse, from the packinghouse to the wholesale market, and also from the packinghouse to other preparation centres such as supermarkets or wet markets.

The container has been designed to allow stacking without damaging the produce. Cushioning materials such as banana leaves and old newspapers may be used to avoid bruising and damage during handling.

Corrugated fibreboard (CFB) cartons are also used for bulk packing of rambutan mainly for export. However, the box has the disadvantage of absorbing moisture and losing strength. The box design and strength must be given great consideration. The moisture barrier inside the package must not impede essential airflow through container vents. The use of banana leaves and polyethylene bags is suitable when packing rambutan using CFB cartons.

The use of bamboo baskets is not common nowadays. These containers are highly unsuitable because fruits may be susceptible to mechanical injury especially from the sharp edges and surfaces of the bamboo basket. Furthermore stacking is a problem as there will be an exertion of pressure on the fruits at the bottom of the container. This may lead to injury and blemishes. However, if bamboo baskets have to be used, then proper precautions such as limiting the size of the basket, the use of cushioning materials, avoiding of high stacking during handling, storage and distribution are necessary.

Packing for export

For export, single rambutan should be packed loosely in a 22 x 31 x 9 cm cardboard box, in uniform rows with the same size, colour and maturity. The fruit are arranged lying down and in two layers. Net weight of the box varies from 2 to 4 kg depending on importer requirements. This type of packing is suitable for transport by air. A carton having a net weight of 16 kg is suitable for sea transport.

The domestic market prefers rambutan fruit packed as fruit bouquets. Fruit to be repacked into fruit bouquets at the retail market can be transported in baskets made of bamboo or plastic. The hairs act as natural cushion to protect the flesh from injury.

Labelling

Each carton for export is labelled with the names of the produce and producer and the net weight. |

| |

|

| |

The shelf life of rambutans is limited. The fruit can be kept only for 1-2 days at ambient temperatures. Optimum storage conditions for both waxed and unwaxed rambutan are 8 to 15 °C with 90 to 95% RH to achieve a storage-life of 14 to 16 days. There may be changes in the skin and spine colouration after storage, but the flesh is unaffected. Waxed fruit maintains its bright skin colour while unwaxed fruit appears darker after 2 weeks. Weight loss of waxed and unwaxed fruit is negligible and is less than 1.5%.

If the fruit is stored longer at this temperature, diseases will attack the fruit. The diseases appear as watery patches on the skin which later turn brown. The rotting later spreads to the flesh.

However by using modified atmosphere packaging, the fruits can be kept for 5-6 days. It is important to plan the harvesting based on the date and the volume required by the buyer so that the fruit can be distributed for marketing on the day itself. However, if storage is required, it should be done correctly to maintain quality. Low temperature storage using cold room is recommended in keeping the rambutan for 2-3 weeks at 10 °C.

If rambutans are stored at 5 °C they will last up to 3 weeks, however t he skin and hair of the fruit will turn black and shrivelled but the aril remains good. Hence the skin becomes thinner and the fruit appears smaller in size. This phenomenon is called chilling injury and this is a physiological disorder caused by low temperature storage. |

| |

|

| |

Transportation and distribution to various markets should be done as soon as possible after packing operations to avoid deterioration, especially wilting. Small or medium sized lorries or vans may be used to transport the fruit to retail outlets. It is important to arrange the produce properly to allow suitable ventilation within the produce. It is advisable to plan the journey at night, early in the morning or late evening to reduce the effect of heat from the sun. The vehicle has to be covered with a tarpaulin sheath to avoid exposure to extreme weather conditions during transportation. Extreme care is needed during loading and unloading.

Export markets

Shipment should be by air, not more than 24 hours after harvest, and preferably with refrigeration. Rambutan can be stored for six days at 12°C before discolouration of the skin occurs. Exposure to higher or lower temperatures results in rapid loss of quality. Skin discolouration occurs at 3 days at tropical room temperature (26°-30°C). Significant weight losses also occur the longer the rambutan is kept in storage, although these can be reduced by storing at lower temperatures and wrapping the fruit in sealed or perforated polyethylene bags (though storing fruit at or below 7°C causes chilling injury and a reduction in the eating quality of the fruit). |

| |

|

| |

Research has shown that fruits stored in sealed polythene bags, without ventilation holes, have a longer shelf-life than those stored unsealed.

An atmosphere of 3-5% O2 and 7-12% CO2 reduces respiration rate and slows down red colour loss and other ageing symptoms. Potentially rambutan can be stored for up to 4 weeks in a controlled atmosphere (as opposed to 2 weeks in air).

Control strategies for effective post-harvest disease control include careful handling to minimize physical damage, proper sanitation, and good temperature and humidity management.

Research has shown that Trichoderma harzianum had antagonistic effects against two postharvest pathogens of rambutan: Glomerella cingulata ( anthracnose ) and Lasiodiplodia theobromae (brown pod rot) . The occurrence of these post-harvest diseases was reduced, whilst maintaining the overall quality and colour of the fruits.

Rambutan is a fruit fly host , and the treatments such as irradiation (250 Gy) and heat treatment (fruit centre to about 49°C) have the potential to destroy insects that are of quarantine concern in importing countries Heat treatment leads to rapid loss of skin colour. |

| |

|

| |

|

| |

| |

| |

|

|

|

|

| Names |

| |

|

|

|

Nepthelium lappaceum

|

|

|

Common: |

|

English: |

Rambutan |

Indonesia: |

Rambutan |

Malaysia: |

Rambutan |

Tagalog (Philippines): |

Rambutan |

Thai: |

Ngoh |

| Tamil: |

Rambutan |

Mandarin: |

Hongmaodan |

Vietnam: |

Choâm choâm |

Cambodian: |

Ser mon, Chle sao mao |

|

|

Taxonomic Position: |

| |

|

Domain: |

Eukaryota |

Kingdom: |

Viridiplantae |

Phylum: |

Spermatophyta |

| Subphylum: |

Angiospermae |

Class: |

Dicotyledonae |

Order: |

Sapindales |

Family: |

Sapindaceae |

| |

|

| Other Names Used: |

| |

| Nephelium chryseum |

| Nephelium sufferrugineum |

|

|

|

|

|

| |

| |

|