Dragon fruit (Hylocereus undatus) is one of Vietnam’s key exports. The development of production models that satisfy Good Agricultural Practices (GAP) standards opened Vietnam’s dragon fruit to markets such as China, USA, Southeast Asian countries, and European countries.

Although the annual fruit export shows signs of growth, the competitiveness of Vietnamese dragon fruit is at risk due to a relatively high price and unstable fruit quality at distant markets.

Although the annual fruit export shows signs of growth, the competitiveness of Vietnamese dragon fruit is at risk due to a relatively high price and unstable fruit quality at distant markets.

Fruit quality requirements may differ in each consumptive markets. Rejections of fruit are partly due to improper postharvest management practices, especially temperature management. This leads to rapid degradation of eating quality and fruit rot. Temperature management is affected by variety, season, and storage conditions. Strict maintenance of the cold chain and the time-temperature relationships are critical to maintain high fruit quality.

For white flesh dragon fruit cultivar, researchers at Southern Horticultural Research Institute ( SOFRI) had reported that the optimal storage temperature of fruit was 5°C and under this storage temperature, the dragon fruit quality could be maintained up to 4 weeks of storage. It was also shown that under a condition of using low temperature conditionings prior to storage at 3°C, fruit quality could be maintained up to 6-8 weeks after harvest. This indicate that the efficiency of temperature management has extremely important significance, and that with good temperature management regime, longer postharvest life with a low rot incidence of dragon fruit may be obtained.

A survey was recently conducted to further assess the effect of temperature on fruit quality during export of the fruit in precooled and non-precooled containers to Holland.

Postharvest management prior to export

The fruits were ensured to be of high quality as they were harvested from orchards that comply with GAP standards. They weighed about 400g each, had firm green bracts and stems, a bright red skin color, and no defects. The fruits were harvested by hand and placed in 40kg plastic crates before the transportation to the packinghouse.

In normal packinghouse practice for dragon fruit, stems were trimmed and the fruits were washed in clean water. They were then soaked in Umikai solution and dried by fan before being packed in perforated polyethylene bags. Next, fruits are packed in a carton box with a capacity of 9 fruits. Each box only contains one layer of fruit to preserve fruit quality. The carton boxes were then loaded in refrigerated containers.

The fruit temperature was monitored and the cooling rate was tested for different air flows. It was found that the most practical solution to cool the fruits faster was to hold fruit in the storage at a high air flow near the evaporator fans for 2-3 days. Overnight cooling would require the use of a forced-air or “precooling” system.

Postharvest management in Holland

Postharvest management in Holland

The importer is located 15 km from port and the container arrives within a few hours of unloading from the ship. The boxes were then taken out of container and placed in a handling area with the temperature of 8-10 °C. The fruits were unloaded by hand and stacked onto pallets. The fruits were then assessed for their quality before they were placed in coolstores equipped with ethylene scrubbers at 2°C.

Quality assessment

It took 23 days for the fruits to arrive from Vietnam to Holland. The temperatures of the containers were maintained at 5oC.

It was found that the temperature of fruits recorded by dataloggers in the pre-cooled container reached 6°C after 1-2 days of loading, while for the no precooled container, temperature only reached 7°C after 5-7 days of loading.

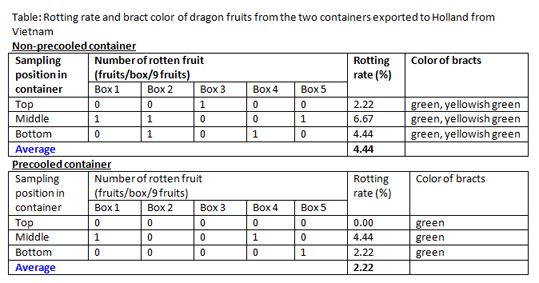

Although fruit temperature between two containers was different, the differences in skin color were negligible. However, fruits in pre-cooled containers had a lower rotting rate of 2.22% compared to the control at 4.44% rotting rate. The bracts in the control were also considerable yellower.

Another observation from the survey showed that the present postharvest management practices (no precooling) would be acceptable in the dry season (mid November-beginning May), however, it would result in problems due to high rot incidence in the wet season when precooling is recommended.

________________________

This article is adapted from a presentation by Nguyen Van Phong, Southern Horticultural Research Institute (SOFRI), Vietnam at the International Symposium on Superfruits: Myth or Truth, Vietnam, 1-3 July 2013

Photos are taken from the powerpoint presentation.