A major constraint in rambutan export is the rapid deterioration of fruit quality and visual appearance. The fruit is high in water content and is prone to desiccation, resulting to an unappealing shriveled form. They are also susceptible to pathological breakdown from bacteria and fungi, characterized by dry hairs or spinterns.

A major constraint in rambutan export is the rapid deterioration of fruit quality and visual appearance. The fruit is high in water content and is prone to desiccation, resulting to an unappealing shriveled form. They are also susceptible to pathological breakdown from bacteria and fungi, characterized by dry hairs or spinterns.

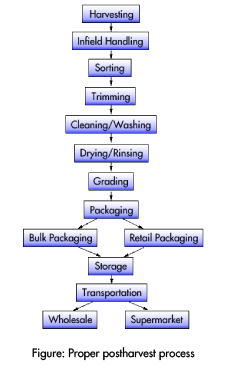

Several postharvest measures can be implemented to preserve fruit quality.

Harvesting

The proper time for harvesting varies with climate, variety and intended use. For domestic consumption, fruits should be harvested at the maturity for the peak in flavor and nutrition. In most varieties, fruits should be picked when the spinterns are in full red color. For export markets, rambutan should be picked when the fruit body has turned red but the spinters are still green. This allows for a longer shelf life of exported fruits.

From the field to the packinghouse

In the field, harvested fruits should be placed in reusable plastic containers because they offer protection from transportation in rugged terrain. Banana leaves or old newspaper can be used to line the container and prevent bruising. Each container should not be excessively loaded with produce to reduce fruit injury. Harvested rambutan should not be exposed to direct sunlight and left on bare soil for long periods to prevent wilting and contamination, respectively.

In the field, harvested fruits should be placed in reusable plastic containers because they offer protection from transportation in rugged terrain. Banana leaves or old newspaper can be used to line the container and prevent bruising. Each container should not be excessively loaded with produce to reduce fruit injury. Harvested rambutan should not be exposed to direct sunlight and left on bare soil for long periods to prevent wilting and contamination, respectively.

To avoid quality deterioration, the fruits must be immediately transported to the packinghouse. The stacking height, arrangement, and ventilation of containers should be considered during loading. Conventional trucks should be covered with a tarpaulin sheet during transportation. Care should also be observed during unloading.

Sorting

Freshly harvested rambutan are sorted for uniformity in size, shape and colour. Heavily bruised, discolored, decayed, and irregular-shaped fruits should be removed. Fruits with symptoms of disease should also be rejected to avoid contamination.

Washing

Adequate washing not only removes the dirt and chemical residue, it also provides a pre-cooling effect to the fruits. To reduce the incidence of decay, a sodium hypochloride solution is added to the wash water (100ppm). The washing water should only be used for a certain number of batches – it should be changed regularly to avoid contamination.

Drying

Drying removes the excess water on the surface of the fruits. The most ideal method to achieve this is through the use of a spinner. However, the machine’s speed must be controlled to avoid bruises to the spinterns.

Grading

There are several Malaysian standards of specification developed by Standards and Industrial Research Institute of Malaysia (SIRIM) that could be used as guidelines for the grading rambutan. This is usually manually carried out based on size, color, maturity, and the presence free of diseases, insect damage, and mechanical injury.

Packaging

The fruits are easier to distribute if properly packed. Regular polyethylene bags and containers are packaging materials for retail packaging. For bulk packaging, reusable high density plastic containers are used for transportation from the farm to the packinghouse, the wholesale market, and their destinations.

The fruits are packed in corrugated fiberboard (CFB) cartons for export. Banana leaves and polyethylene bags are used to pack the rambutan in these cartons to ensure freshness and retain moisture.

Storage and transportation

The shelf life of rambutan is limited due to the wilting, browning, and blackening. Once the skin wilts, shelf life is reduced to only 1-2 days. However, modified atmosphere packing can be used to keep rambutan fruits fresh for 5-6 days. It is important to plan the harvesting based on the date and the volume required by the buyer. The fruit should be distributed immediately after harvesting. If storage is needed, the fruits should be kept in a cold room at 10°C. This extends the shelf life to 2 weeks.

The products must be immediately transported and distributed to various markets. The produce must be properly arranged to allow ventilation within the package. It is advisable to transport at night, early in the morning, or late in the evening to reduce deterioration from the high temperature.

by Latifah Mohd Nor & AbAziz Ibrahim, MARDI, Malaysia